It is becoming more common practice for commercial and residential structures of all types to use aluminum veneers on their facades because this material is not only practical but also aesthetically pleasing. In this article, we will explain what is custom aluminum veneer as well as the benefits that come along with using it.

What is aluminum veneer?

Let’s know what is custom aluminum veneer. A substrate, often plywood or metal studs is used in the production of aluminum veneers, which are produced from very thin sheets of aluminum that are bonded to the substrate. The application of processing following chroming and other treatments, followed by the application of fluorocarbon coating technology, results in the formation of an aluminum veneer as a building decorative material. In addition, as a result of its many advantages, including its longevity, fire resistance, and energy efficiency, it is becoming an increasingly preferred choice for the cladding of buildings.

The process of construction:

There are currently two different types of aluminum veneers that can be found all over the world. These include fluorocarbon-sprayed aluminum veneers as well as roller coatings. In this business, the manufacturing of fluorocarbon coating is the primary focus of the veneers’ processing procedure. The process of spraying aluminum sheets can be broken down into two main steps:

- The first step is sheet metal processing.

Cutting, folding, bending, welding, and grinding the flat plate are the primary steps in this procedure. These steps are carried out to transform the aluminum veneer into the shape and size required for the building.

- Spraying:

Spraying is the second phase in the process. The sheet metal that has been treated is sprayed with paint during the spraying process. Spraying can be done manually or with a machine; both methods provide similar results. Manual spraying is the more common method. Machine spraying is often only suited for standard flat plates. However, this type of aluminum veneer is utilized less in practical use, and the majority of local manufacturers choose manual spraying.

Manual spraying is a hazardous job since paint is highly flammable and toxic, and it is simple to develop chronic benzene series poisoning, which can have huge consequences for a person’s health. One of the many significant benefits of manual spraying is that the color can be optional, regardless of the amount of color that is applied. However, the amount of roll coating that must be applied to the aluminum composite panel before processing must meet a particular threshold.

Features of aluminum veneer:

- Aluminum veneers have many advantages over other materials, such as ceramic sheets and glass, including their low weight, great strength, and good rigidity, as well as their ease of processing.

- It offers exceptional resilience to adverse weather conditions and ultraviolet light (UV) as a result of the PVDF coating.

- It retains its color and gloss over time, has high corrosion resistance, and can be utilized in severe temperatures ranging from -50 degrees Celsius to 80 degrees Celsius.

- It has high resilience to both acids and alkalis.

- It has an excellent performance in processing, is simple to cut, weld, and bend is capable of being formed, and is straightforward to install at the site.

- On the aluminum veneer, the sound insulation and shock absorption capabilities are both good, and it is possible to punch holes in any configuration.

- On the back, sound-absorbing cotton, rock wool, and other sound-absorbing and heat-insulating materials can be added. In the case of a fire, these materials have good flame retardancy and do not emit hazardous gases.

- The color may be customized to have a wide range, and it has a stunning appearance.

- They are simple to clean and maintain, as well as compliant with regulations governing environmental protection.

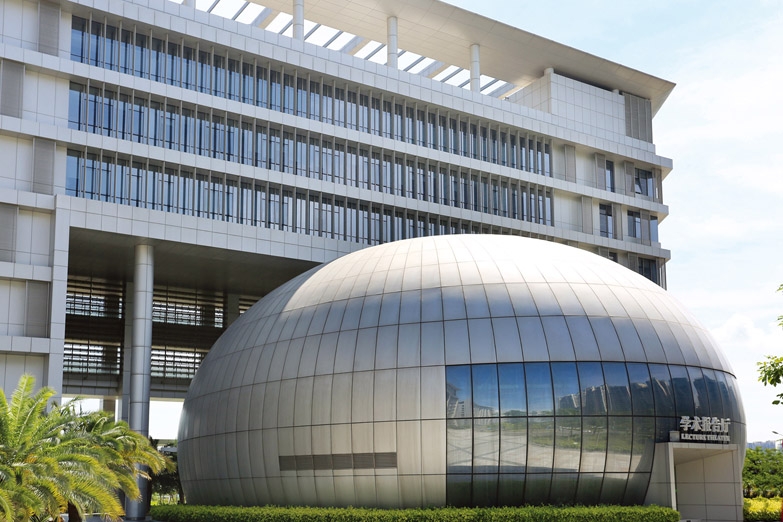

- It is also possible to utilize aluminum veneers in conjunction with glass curtain walls in order to give structures a more refined and noble appearance.

Applications of aluminum veneer:

Cabinetry, banquettes, planter boxes, fireplaces, hollow metal doors, bar wrapping, millwork, and many other things can all be decorated with aluminum veneers, which are a type of decorative building material. They are also used extensively for decorating the interior and exterior walls of a variety of buildings, as well as overhead walkways, elevators, advertising boards, reception desks, signage, escalators, staircases, and signage.

Aluminum veneer for decoration:

One of the most popular forms of aluminum construction material now used in the building industry is aluminum veneer. The products have a wide variety of hues, including yellow, white, and others. Architectural decorating can benefit from aluminum veneer’s ability to inspire novel design concepts and expand available options. After that, the industry of aluminum veneer developed swiftly, and the technology continued to advance and advance rapidly. When it comes to the construction of buildings, such as exterior walls, it is the material of choice for architects and engineers. An aluminum veneer is a significant component not only in the building process but also in the decorative process.

Aluminum veneer as curtain wall:

After the success of the glass curtain wall, a new form of the curtain wall was developed: the aluminum veneer curtain wall. Many architects, interior designers, and property owners will opt for aluminum veneer curtain walls over glass curtain walls because the aluminum veneer is superior in every way.

The veneer curtain wall has a surface that is decorated with a variety of colors and designs. It offers decorative effects that are superior to those of the glass curtain wall. It is simple to clean and maintain, and it is also recyclable, which contributes to a reduction in energy consumption and is better for the environment. In most cases, aluminum veneer is the superior material to use for the ornamentation of curtain walls.

In the meantime, the aluminum veneer curtain wall is one of the most common products that can be used for the decoration of a variety of different building interior and exterior walls, lobby facades, elevated corridors, pedestrian bridges, elevator edging, balcony packaging, advertising signs, indoor special-shaped ceilings, and so on.

Benefits:

Following are a few benefits of aluminum veneer:

- Good fire protection function:

The fire rating of aluminum veneer material is as high as A2, and the melting point is as high as 660 degrees, making it one of the excellent fire-prevention construction materials. According to the accounting of the fire protection section, the fire rating of aluminum veneer material is as high as A2. The use of aluminum veneer that has been certified by the state is also permitted. We can utilize it to center ourselves, as well as carry out building directly.

- Good sound insulation effect:

The section of the national accounting that is pertinent to the topic states that the sound insulation provided by aluminum veneer material can reach as high as 39-32 decibels. The use of aluminum veneer in material planning is very extensive; it can be used for both bedrooms and studies, and it can also be used for airports and high-speed train stations. If there is anything else you can’t think of that aluminum veneer can’t do, it’s probably not possible to use aluminum veneer.

- Moisture-proof and corrosion-proof:

Since aluminum veneer material has all the qualities of wood but also has the moisture-proof effect of wood and will not fracture due to thermal expansion and cold contraction, this material is more suitable for use on ceilings.

- Excellent heat preservation and insulation function:

The general building materials consist of aluminum veneer sheet, which has the functions of preserving heat and insulating against heat. Because the summers in the south of our country are hot and the winters in the north are cold, aluminum veneer material has become the best material for construction because it can be punched by adding sound-absorbing cotton and provides very good satisfaction with its insulation and heat preservation functions.

Maintenance and cleaning:

The aluminum veneer calls for virtually little upkeep and requires very little of it. By adhering to some simple cleaning procedures, surface residue can be eliminated. The aluminum veneer can be cleaned using a commercial neutral detergent that does not include any solvents and is also non-abrasive, along with clean water. It is simple to use, and it is simple to clean. They are built to last for a very long period.

Conclusion:

An aluminum veneer is extremely popular in the industrial culture that we live in today. We opt to utilize aluminum veneer rather frequently because it offers several extremely nice benefits. Excellent work was done in making proper use of the effects. They are a choice for interior millwork that is not only sturdy but also flexible and elegant. When properly produced, these lightweight aluminum veneers are simple to handle and may be bent and molded without cracking or crazing. We hope now you’re clear about what is custom aluminum veneer. The aluminum veneer of the highest quality can be manufactured to your requirements by ManyBest.